Blog

Essential Winter Maintenance Guide for Hydro-Cooling Miners: Preventing Freeze Damage

Hydro-cooling technology has set a new standard for crypto mining efficiency, offering superior heat dissipation and noise reduction. However, operating liquid-cooled ASIC miners in cold climates requires specific maintenance protocols. At Yesmining.io, we have analyzed recent hardware failures caused by sub-zero temperatures to help you protect your investment and maintain your warranty.

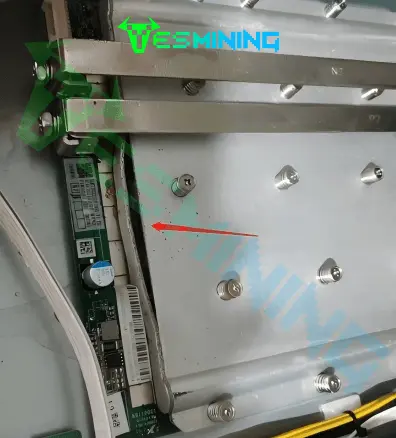

1. Case Study: The Destructive Power of Frozen Coolant

A recent technical analysis of returned units revealed severe structural damage caused by improper handling during winter rework and shipping. The following issues were identified:

Coolant Leakage: Internal ruptures led to liquid escaping the cooling circuit.

Brazing Area Bulging: The immense pressure from ice expansion caused the metal brazing on the hydro board to swell and deform.

Connector Failure: Critical water connectors were found cracked or completely snapped due to the volumetric expansion of frozen liquid.

The Root Cause

These failures typically occur when a miner is moved from a warm indoor environment (e.g., 23°C) to a freezing outdoor environment (e.g., -17°C) without being properly drained. Since water expands when it freezes, any residual liquid trapped inside the hydro board acts like a hydraulic press, destroying the internal structure of the cooling plate from the inside out.

2. Mandatory Maintenance Protocols

To ensure the longevity of your hydro-cooling hardware, every operator must follow these non-negotiable precautions during operation, maintenance, and storage:

A. Use Approved Anti-Icing Fluid: In any region with a risk of freezing, the use of pure water or tap water is strictly forbidden. You must use a professional-grade anti-icing fluid compatible with Bitmain systems to prevent the liquid from solidifying.

B. Deep Cleaning with Air Pumps: Before rework, transfer, or long-term storage, it is required to use an air pump or similar tool to completely blow out and clean up all residual liquid within the hydro board.

C. Seal Before Packaging: Always use dedicated plugs to block the water inlet and outlet before packaging a unit. This prevents any remaining moisture from leaking and protects the internal circuits during transit.

3. Risk Assessment and Warranty Implications

Failure to follow these protocols introduces several high-level risks to your mining operation:

Hardware Destruction: If residual liquid flows onto the hashboard, it can cause a short circuit, leading to burnt chips and a completely scrapped board once powered on.

Packaging Integrity: Leaking fluid can degrade packaging materials, increasing the risk of physical damage during shipping.

Warranty Voidance: Damage caused by freezing, improper drainage, or the use of unapproved liquids is generally classified as user negligence and will void your official warranty.

4. Featured Hydro-Cooling Solutions

For miners looking to upgrade to the latest in liquid-cooling efficiency, Yesmining recommends the following flagship models. These machines offer industry-leading hashrates and are designed for high-performance data centers.

| Product Model | Hashrate | Power Consumption |

|---|---|---|

| Antminer S21 XP Hyd | 473 TH/s | 5676W |

| Antminer S21e XP Hyd (3U) | 860 T | Custom High Density |

Conclusion

Proactive maintenance is the key to maximizing your ROI in the crypto mining industry. By using the correct anti-icing fluids and ensuring your hydro boards are thoroughly dried before movement, you can avoid costly repairs and downtime. For more professional mining hardware and cooling solutions, visit Yesmining.io today.

Bitdeer

Bitdeer Bitmain

Bitmain BOMBAX

BOMBAX DragonBall

DragonBall Elphapex

Elphapex Fluminer

Fluminer Goldshell

Goldshell iBelink

iBelink Iceriver

Iceriver Ipollo

Ipollo Jasminer

Jasminer Volcminer

Volcminer Aleo Miner

Aleo Miner